Ethernet Cable Jacket Types: Rating and Applications in Structured Cabling

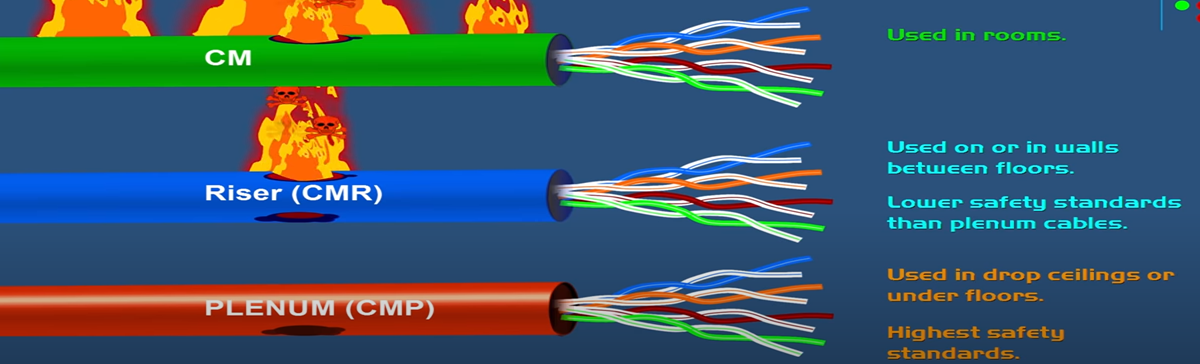

When most people think of Ethernet cables, they focus on speed ratings like Cat5e, Cat6, or Cat6a. But the jacket type—the outer layer of the cable—is just as important. The jacket determines whether a cable can be installed indoors, outdoors, in walls, above ceilings, or between floors. It also defines how safe it is in case of a fire, and whether it can withstand tough environments.

The outermost protective layer of an Ethernet LAN cable, known as the jacket, is far more than just a coating. It plays a critical role in determining the cable’s resistance to environmental factors (like UV, moisture, and abrasion) and, most importantly, its fire safety compliance.

Quick Comparison: Ethernet Jacket Types

| Jacket Type | Typical Material | Fire/Smoke Performance | Best Use Case | Relative Cost |

| PVC (CM) | Polyvinyl chloride | CM (general-purpose) — higher smoke & toxicity | Homes, small offices, patch cords | Low |

| Plenum (CMP) | FEP or Low-Smoke PVC | CMP — highest plenum fire/smoke standard (UL 910/NFPA 90A) | Air-handling spaces (ceilings, ducts) | High |

| Riser (CMR) | Fire-retardant PVC blends | CMR — vertical flame spread (UL 1666) | Vertical shafts, between floors | Medium |

| LSZH | Halogen-free compounds | Low smoke, zero halogen (IEC 60754 / IEC 61034) | Data centers, hospitals, public spaces | Medium–High |

| Direct Burial | Polyethylene (PE), gel-filled; optional armor | Varies; designed for moisture/soil protection | Underground runs, campus links | Medium–High |

| Outdoor-Rated | UV-stabilized PE | Weatherproof; UV resistant | Rooftops, aerial runs, building exteriors | Medium |

| Industrial / Armored | TPU/TPE, steel/aluminum armor | Very robust; often IP67/IP68 rated | Factories, robotics, harsh environments | High |

Why Jacket Types Matter (Beyond the Obvious)

The jacket is not cosmetic. It controls:

- Safety: Flame spread, toxic emissions, and smoke density can be life-critical in an enclosed building.

- Durability: Resistance to UV, moisture, chemicals, rodents and mechanical abuse extends service life.

- Performance under stress: Some jackets influence bend radius, conductor heating (important for PoE), and termination reliability.

- Code compliance: Plenum and riser ratings are often legally required in specific building zones.

- Total cost of ownership: Cheaper jackets may save money up front but can cost more via replacements, downtime, or failed inspections.

Understanding Cable Jacket Basics — What to Check

When comparing jackets, pay attention to:

- Material properties: PE, PVC, FEP, TPU, TPE, halogen-free compounds.

- Temperature rating: The Operating range of the jacket retains mechanical and electrical integrity.

- Flame/smoke tests & standards: CMP/CMR/CM; IEC 60754 (halogen acid gas), IEC 61034 (smoke density), UL 910 (plenum), UL 1666 (riser).

- Mechanical specs: Crush resistance, tensile/pull strength, minimum bend radius, and abrasion resistance.

- Environmental protection: UV resistance, water blocking (gel vs. dry-water block), and armoring against rodents/impact.

- Markings: Look for clear jacket markings (e.g., “Cat6 UTP CMR 23AWG”) and manufacturer datasheet.

Jacket Types

PVC (Polyvinyl Chloride) — The Workhorse

What it is: Thermoplastic polymer with plasticizers for flexibility.

Technical notes: Common temperature ratings around 0–60°C; usually 24 AWG conductors in Cat5e, often 23 AWG in Cat6. Jacket is easy to strip and terminate.

Pros: Low cost, flexible, very widely stocked.

Cons: Produces dense, toxic smoke (halogen gases) when burned; not permitted in plenum spaces. UV and outdoor exposure degrade PVC over time.

Typical uses: Home networks, office horizontal cabling (non-plenum), patch cords, short runs.

Procurement tip: If using PVC, ensure it’s properly routed inside conduits or protected above ceilings as required.

Plenum (CMP) — Highest Fire & Smoke Safety

What it is: Jacket made from FEP or specially formulated low-smoke compounds designed for plenum (air handling) spaces.

Standards: UL 910 (Steiner tunnel), NFPA 90A, NEC Article 800 references.

Technical notes: Higher cost; more difficult to terminate (FEP is tougher to strip); typically rated for higher temperatures (e.g., −20°C to +75°C).

Pros: Minimal smoke, low toxicity, self-extinguishing—critical for occupant safety.

Cons: More expensive; can be stiffer (larger bend radius).

Typical uses: Above drop ceilings used as air plenums, raised floor plenums in data centers, any HVAC air-circulation space.

Procurement tip: Plenum cables must be used where required — riser/CMR or regular CM cables cannot substitute.

Riser (CMR) — Vertical Runs Between Floors

What it is: Fire-retardant jacket (PVC blend) certified for vertical shaft use.

Standards: UL 1666 vertical flame test; NEC Article 800 compliance for riser shafts.

Technical notes: Moderately priced; easier to work with than plenum cable while offering improved flame resistance over standard CM.

Pros: Good compromise for multi-floor buildings where plenum rating isn’t required.

Cons: Not allowed in plenum spaces.

Typical uses: Elevator shafts, riser shafts, stairwell vertical runs, inter-floor trunking.

Installation note: Follow building codes for penetrations and firestopping at floor transitions.

LSZH (Low Smoke Zero Halogen) — Low Toxicity, Safer Environments

What it is: Halogen-free compound; when burned, it emits minimal smoke and no corrosive halogen gases (chlorine, bromine).

Standards: IEC 60754 (halogen acid gas), IEC 61034 (smoke density). Widely specified across international projects.

Pros: Safer for people and electronics; minimizes corrosive fumes that can damage equipment.

Cons: Generally stiffer, can be more expensive (30–60% above cheap PVC), some formulations are more sensitive to low temperatures.

Typical uses: Hospitals, data centers, public transportation, ships, schools, confined spaces where occupant safety and equipment protection matter.

Procurement tip: Check manufacturer datasheets for exact IEC test results and temperature ratings; ensure LSZH compound meets both smoke and halogen tests.

Direct Burial — Underground Toughness

What it is: PE (polyethylene) jacket, often gel-filled core or dry water-blocking tape; armor options (steel tape/corrugated armor) for rodent and mechanical protection.

Features: Waterproof, UV stable, designed to sit in soil with chemical resistance and crush tolerance.

Installation notes: Typical minimum burial depth 450–600 mm (18–24 inches) depending on local code and expected mechanical loads; use warning tape above cable; consider conduit if future access is anticipated.

Pros: Can be buried without conduit (if cable is designed for it), good for campus links.

Cons: More costly; damaged cables require excavation; armoring complicates termination.

Procurement tip: Choose gel-filled for permanent burial; choose dry waterblocking for easier termination in some projects; confirm crush rating and chemical resistance for local soils.

Outdoor Rated (Aerial / Exposed) — UV & Weather Resistant

What it is: UV-stabilized polyethylene jackets, often black carbon-filled, designed for aerial and exposed runs; may include messenger wire support.

Features: Wide temperature range (e.g., −40°C to +75°C), ozone and UV resistance, moisture protection, sometimes flooded cores.

Installation tips: Use proper messenger support for long aerial spans; add expansion loops to accommodate thermal expansion; install drip loops at building entry points to prevent water ingress.

Pros: Durable outdoors without rapid degradation.

Cons: Less flexible; not intended for burial unless specifically rated.

Industrial & Armored — Built for Abuse

What it is: Heavy-duty jackets (TPU/TPE), sometimes with steel or aluminum armor; designed for continuous flex (robotics), oil/chemical resistance, and mechanical stress.

Standards: Often IP67/IP68 for connectors/cables in industrial environments.

Features: Continuous flex life (millions of cycles), tight bend radius, torsion resistance, abrasion resistance.

Typical uses: Robotic arms, drag chains, factory floors, food processing (FDA options), cleanrooms.

Procurement tip: Look for flex-life ratings, chemical compatibility lists, and relevant industrial certifications.

Installation & Performance Considerations (Practical Guidance)

Bend Radius & Pulling Tension

- Respect the minimum bend radius — typically 4× cable diameter for solid jacketed cable; tighter radii reduce lifespan and may increase crosstalk.

- Observe pulling tension limits noted in the datasheet; exceeding them damages pairs and affects performance.

Conduit vs Open Air

- In plenum spaces or where mechanical protection is required, conduit may be necessary despite cable jacket ratings.

- Outdoor aerial runs require messenger support; buried runs may require conduit in high-risk areas.

Routing & Segregation

- Keep Ethernet runs away from high-voltage power cables (cross at 90° where unavoidable).

- For high-EMI environments consider shielded cable with proper grounding (STP/FTP), and jacket choices that complement the shield.

PoE Considerations

- PoE and PoE+ increase conductor current; in large bundles, heat can accumulate and reduce current carrying capacity. Use cables with adequate conductor gauge (23 AWG vs 24 AWG) and consider derating in dense bundles.

Termination & Testing

- Some jackets (FEP/CMP) require special tools to strip without damaging conductors.

- After installation, certify links with a cable tester (wiremap, NEXT/FEXT, attenuation, return loss, and length).

- Document cable runs, labels, and maintain as-built drawings for fire inspections.

Procurement Checklist — What to Ask the Supplier

- Datasheet & Test Reports: UL / IEC certifications, smoke/toxicity and flame test results.

- Jacket Markings: Confirm printed legend (category, jacket rating, conductor gauge).

- Temperature & Mechanical Specs: Operating range, crush rating, tensile/pull limits.

- Shielding & Conductor Details: UTP vs FTP/STP, AWG of conductors.

- Water blocking & Armor: Gel vs dry water-blocking, armor type and termination method.

- Warranty & Service Life: Expected service life (15–20 years typical) and warranty coverage.

- Local Support & Stock: Lead times, local stock, replacement policy.

III. LSZH vs. Plenum (CMP)

LSZH and CMP are often compared as they both offer enhanced fire safety, but they serve slightly different purposes based on global standards:

| Feature | CMP (Plenum) | LSZH (Low Smoke Zero Halogen) |

| Primary Goal | Minimize flame spread and smoke in air-handling (plenum) environments (NEC standard). | Eliminate toxic, corrosive halogens and minimize smoke (IEC standard, popular in Europe). |

| Toxicity | Releases very low smoke, but may still contain halogens. | Zero halogens, minimal smoke, protecting people and sensitive electronics (which can be damaged by corrosive halogen fumes). |

| Flexibility | Less flexible and more expensive than CMR/CM. | Less flexible than PVC and often requires careful installation. |

| Substitution | Can be used anywhere (CM, CMR, CMP spaces). | Primarily for indoor public/enclosed spaces where human safety is paramount. |

Cost vs Value — How to Balance Budget and Safety

- PVC is cost-efficient for non-critical, protected indoor runs.

- LSZH and CMP cost more but reduce life-safety risk and can be legally required.

- Direct burial and armored cables cost more but prevent repeated replacement and downtime in harsh environments.

- Consider total cost of ownership: initial cable cost + installation + compliance + potential retrofit.

Quick FAQ (Short Answers for Common Questions)

Q: Is LSZH better than PVC?

A: For fire safety and protecting sensitive electronics, yes — LSZH emits far less toxic gas. For simple protected office runs, PVC is acceptable and cheaper.

Q: Do I need plenum cable?

A: Use CMP where cable will be in air handling spaces (drop ceilings, plenum cavities). Local building codes dictate requirements.

Q: Can I use outdoor cable indoors?

A: You can, but outdoor cables are often stiffer and may not be ideal for indoor routing. Use the jacket that best fits the environment and code.

Q: Direct burial vs outdoor cable — what’s the difference?

A: Direct burial is specifically designed to be buried without conduit (gel-filled, armoring options). Outdoor cable is for exposed above-ground runs and aerials.

Q: How deep should I bury Ethernet cable?

A: Typical practice is 450–600 mm (18–24 inches), but check local codes and expected traffic loads; conduit may be required in some areas.

Q: Will PoE heat cables in bundles?

A: Yes — dense bundled cables carrying PoE can heat up; consider conductor gauge (23 AWG better than 24 AWG), reduced bundle sizes, or derating.

Conclusion

Selecting the right ethernet cable jacket is a critical decision that impacts network performance, safety, and long-term reliability. From cost-effective PVC jackets for standard office installations to specialized plenum-rated, LSZH, and industrial cables for demanding environments, each jacket type serves specific purposes and addresses unique challenges. Understanding the characteristics, applications, and code requirements for different cable jackets enables informed decisions that ensure both optimal performance and regulatory compliance.

The key to successful cable selection lies in thoroughly assessing your installation environment, understanding applicable fire safety codes, and matching jacket specifications to actual operating conditions. While it may be tempting to minimize costs with standard PVC cables, investing in appropriate jacket types for specific applications prevents premature failures, ensures code compliance, and ultimately reduces total cost of ownership. Whether installing ethernet cables in office buildings, data centers, industrial facilities, or outdoor environments, choosing the right jacket material is essential for building robust, reliable network infrastructure that serves your organization for years to come.

Ready to select the perfect ethernet cables for your project? Shop our complete range of ethernet cables with various jacket types including PVC, plenum-rated, riser, LSZH, and outdoor options. Our expert team can help you choose the right cable jacket specifications to meet your performance, safety, and compliance requirements.